How to make a charger for a 12V battery with your own hands. Homemade charger for a car battery: diagrams, instructions. Operating principle of the charger

Often car owners have to deal with the phenomenon of the inability to start the engine due to a low battery. To solve the problem, you will need to use a battery charger, which costs a lot of money. In order not to spend money on buying a new charger for a car battery, you can make it yourself. It is only important to find a transformer with the necessary characteristics. To make a homemade device, you don’t have to be an electrician, and the whole process will take no more than a few hours.

Features of battery operation

Not all drivers know that lead-acid batteries are used in cars. Such batteries are distinguished by their endurance, so they can last up to 5 years.

To charge lead-acid batteries, a current equal to 10% of the total battery capacity is used. This means that to charge a battery with a capacity of 55 A/h, a charging current of 5.5 A is required. If a very high current is applied, this can lead to boiling of the electrolyte, which, in turn, will lead to a decrease in service life devices. A small charging current does not extend the life of the battery, but it does not have a negative impact on the integrity of the device.

This is interesting! When a current of 25 A is supplied, the battery is quickly recharged, so within 5-10 minutes after connecting a charger with this rating, you can start the engine. Such a high current is produced by modern inverter chargers, but it negatively affects the battery life.

When charging the battery, the charging current flows back to the working one. The voltage for each can should not be higher than 2.7 V. A 12 V battery has 6 cans that are not connected to each other. Depending on the battery voltage, the number of cells differs, as well as the required voltage for each cell. If the voltage is higher, this will lead to a process of decomposition of the electrolyte and plates, which contributes to the failure of the battery. To prevent the electrolyte from boiling, the voltage is limited to 0.1 V.

The battery is considered discharged if, when connecting a voltmeter or multimeter, the devices show a voltage of 11.9-12.1 V. Such a battery should be recharged immediately. A charged battery has a voltage at the terminals of 12.5-12.7 V.

Example of voltage at the terminals of a charged battery

The charging process is the restoration of spent capacity. Charging batteries can be done in two ways:

- D.C. In this case, the charging current is regulated, the value of which is 10% of the device capacity. Charging time is 10 hours. The charging voltage varies from 13.8 V to 12.8 V for the entire charging duration. The disadvantage of this method is that it is necessary to control the charging process and turn off the charger in time before the electrolyte boils. This method is gentle on the batteries and has a neutral effect on their service life. To implement this method, transformer chargers are used.

- Constant pressure. In this case, a voltage of 14.4 V is supplied to the battery terminals, and the current changes from higher to lower values automatically. Moreover, this change in current depends on such a parameter as time. The longer the battery is charged, the lower the current becomes. The battery will not be able to be recharged unless you forget to turn off the device and leave it for several days. The advantage of this method is that after 5-7 hours the battery will be charged by 90-95%. The battery can also be left unattended, which is why this method is popular. However, few car owners know that this charging method is “emergency”. When using it, the service life of the battery is significantly reduced. In addition, the more often you charge in this way, the faster the device will discharge.

Now even an inexperienced driver can understand that if there is no need to rush into charging the battery, then it is better to give preference to the first option (in terms of current). With accelerated charge recovery, the service life of the device is reduced, so there is a high probability that you will need to buy a new battery in the near future. Based on the above, the material will consider options for manufacturing chargers based on current and voltage. For production, you can use any available devices, which we will discuss later.

Battery charging requirements

Before carrying out the procedure for making a homemade battery charger, you must pay attention to the following requirements:

- Providing a stable voltage of 14.4 V.

- Device autonomy. This means that a homemade device should not require supervision, since the battery is often charged at night.

- Ensuring that the charger turns off when the charging current or voltage increases.

- Reverse polarity protection. If the device is connected to the battery incorrectly, the protection should be triggered. For implementation, a fuse is included in the circuit.

Polarity reversal is a dangerous process, as a result of which the battery may explode or boil. If the battery is in good condition and only slightly discharged, then if the charger is connected incorrectly, the charging current will increase above the rated one. If the battery is discharged, then when the polarity is reversed, an increase in voltage above the set value is observed and, as a result, the electrolyte boils.

Options for homemade battery chargers

Before you start developing a battery charger, it is important to understand that such a device is homemade and can negatively affect the battery life. However, sometimes such devices are simply necessary, as they can significantly save money on purchasing factory-made devices. Let's look at what you can make your own battery chargers from and how to do it.

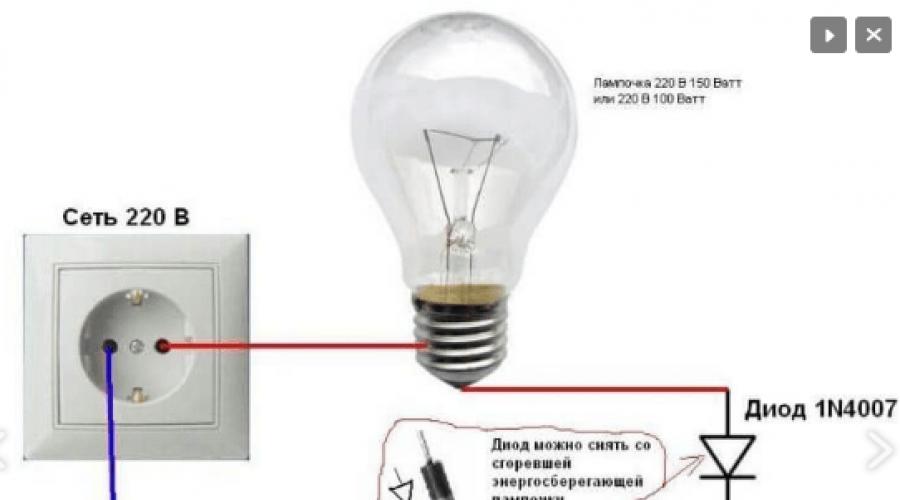

Charging from a light bulb and a semiconductor diode

This charging method is relevant in situations where you need to start a car on a dead battery at home. In order to do this, you will need the components to assemble the device and a 220 V alternating voltage source (socket). The circuit of a homemade charger for a car battery contains the following elements:

- Incandescent lamp. An ordinary light bulb, which is also popularly referred to as “Ilyich’s lamp.” The power of the lamp affects the charging speed of the battery, so the higher this indicator, the faster you can start the engine. The best option is a lamp with a power of 100-150 W.

- Semiconductor diode. An electronic element whose main purpose is to conduct current only in one direction. The need for this element in the charging design is to convert alternating voltage to direct voltage. Moreover, for such purposes you will need a powerful diode that can withstand a heavy load. You can use a diode, either domestic or imported. In order not to buy such a diode, it can be found in old receivers or power supplies.

- Plug for connecting to a socket.

- Wires with terminals (crocodiles) for connecting to the battery.

It is important! Before assembling such a circuit, you need to understand that there is always a risk to life, so you should be extremely careful and cautious.

Connection diagram of a charger from a light bulb and a diode to a battery

The plug should be plugged into the socket only after the entire circuit has been assembled and the contacts have been insulated. To avoid the occurrence of short circuit current, a 10 A circuit breaker is included in the circuit. When assembling the circuit, it is important to take into account the polarity. The light bulb and semiconductor diode must be connected to the positive terminal circuit of the battery. When using a 100 W light bulb, a charging current of 0.17 A will flow to the battery. To charge a 2 A battery, you will need to charge it for 10 hours. The higher the power of the incandescent lamp, the higher the charging current.

It makes no sense to charge a completely dead battery with such a device, but recharging it in the absence of a factory charger is quite possible.

Battery charger from rectifier

This option also falls into the category of the simplest homemade chargers. The basis of such a charger includes two main elements - a voltage converter and a rectifier. There are three types of rectifiers that charge the device in the following ways:

- D.C;

- alternating current;

- asymmetrical current.

Rectifiers of the first option charge the battery exclusively with direct current, which is cleared of alternating voltage ripples. AC rectifiers apply pulsating AC voltage to the battery terminals. Asymmetric rectifiers have a positive component, and half-wave rectifiers are used as the main design elements. This scheme has better results compared to DC and AC rectifiers. It is its design that will be discussed further.

In order to assemble a high-quality battery charging device, you will need a rectifier and a current amplifier. The rectifier consists of the following elements:

- fuse;

- powerful diode;

- Zener diode 1N754A or D814A;

- switch;

- variable resistor.

Electrical circuit of an asymmetric rectifier

In order to assemble the circuit, you will need to use a fuse rated for a maximum current of 1 A. The transformer can be taken from an old TV, the power of which should not exceed 150 W, and the output voltage should be 21 V. As a resistor, you need to take a powerful element of the MLT- brand 2. The rectifier diode must be designed for a current of at least 5 A, so the best option is models like D305 or D243. The amplifier is based on a regulator based on two transistors of the KT825 and 818 series. During installation, the transistors are installed on radiators to improve cooling.

The assembly of such a circuit is carried out using a hinged method, that is, all the elements are located on the old board cleared of tracks and connected to each other using wires. Its advantage is the ability to adjust the output current for charging the battery. The disadvantage of the diagram is the need to find the necessary elements, as well as arrange them correctly.

The simplest analogue of the above diagram is a more simplified version, shown in the photo below.

Simplified circuit of a rectifier with a transformer

It is proposed to use a simplified circuit using a transformer and rectifier. In addition, you will need a 12 V and 40 W (car) light bulb. Assembling the circuit is not difficult even for a beginner, but it is important to pay attention to the fact that the rectifier diode and the light bulb must be located in the circuit that is fed to the negative terminal of the battery. The disadvantage of this scheme is that it produces a pulsating current. To smooth out pulsations, as well as reduce strong beats, it is recommended to use the circuit presented below.

A circuit with a diode bridge and a smoothing capacitor reduces ripple and reduces runout

Charger from a computer power supply: step-by-step instructions

Recently, a car charging option that you can make yourself using a computer power supply has become popular.

Initially you will need a working power supply. Even a unit with a power of 200 W is suitable for such purposes. It produces a voltage of 12 V. It will not be enough to charge the battery, so it is important to increase this value to 14.4 V. Step-by-step instructions for making a charger for a battery from a computer power supply are as follows:

- Initially, all excess wires that come out of the power supply are soldered off. You only need to leave the green wire. Its end needs to be soldered to the negative contacts, where the black wires come from. This manipulation is done so that when the unit is connected to the network, the device starts up immediately.

The end of the green wire must be soldered to the negative contacts where the black wires were located

- The wires that will be connected to the battery terminals must be soldered to the minus and plus output contacts of the power supply. The plus is soldered to the exit point of the yellow wires, and the minus to the exit point of the black ones.

- At the next stage, it is necessary to reconstruct the operating mode of pulse width modulation (PWM). The TL494 or TA7500 microcontroller is responsible for this. For reconstruction you will need the lower leftmost leg of the microcontroller. To get to it, you need to turn the board over.

The TL494 microcontroller is responsible for the PWM operating mode

- Three resistors are connected to the bottom pin of the microcontroller. We are interested in the resistor that is connected to the output of the 12 V block. It is marked in the photo below with a dot. This element should be unsoldered, and then measure the resistance value.

The resistor indicated by the purple dot must be desoldered

- The resistor has a resistance of about 40 kOhm. It must be replaced with a resistor with a different resistance value. To clarify the value of the required resistance, you must first solder a regulator (variable resistor) to the contacts of the remote resistor.

A regulator is soldered in place of the removed resistor

- Now you should connect the device to the network, having previously connected a multimeter to the output terminals. The output voltage is changed using a regulator. You need to get a voltage value of 14.4 V.

Output voltage is regulated by variable resistor

- As soon as the voltage value is reached, the variable resistor should be unsoldered, and then the resulting resistance should be measured. For the example described above, its value is 120.8 kOhm.

The resulting resistance should be 120.8 kOhm

- Based on the obtained resistance value, you should select a similar resistor, and then solder it in place of the old one. If you cannot find a resistor of this resistance value, then you can select it from two elements.

Soldering resistors in series adds up their resistance

- After this, the functionality of the device is checked. If desired, you can install a voltmeter (or an ammeter) to the power supply, which will allow you to monitor the voltage and charging current.

General view of the charger from the computer power supply

This is interesting! The assembled charger has the function of protection against short circuit current, as well as against overload, but it does not protect against polarity reversal, so you should solder the output wires of the appropriate color (red and black) so as not to mix them up.

When connecting the charger to the battery terminals, a current of about 5-6 A will be supplied, which is the optimal value for devices with a capacity of 55-60 A/h. The video below shows how to make a charger for a battery from a computer power supply with voltage and current regulators.

What other charger options are there for batteries?

Let's consider a few more options for independent battery chargers.

Using a laptop charger for the battery

One of the simplest and fastest ways to revive a dead battery. To implement the scheme for reviving the battery using charging from a laptop, you will need:

- Charger for any laptop. The charger parameters are 19 V and the current is about 5 A.

- Halogen lamp with a power of 90 W.

- Connecting wires with clamps.

Let's move on to the implementation of the scheme. The light bulb is used to limit the current to an optimal value. You can use a resistor instead of a light bulb.

A laptop charger can also be used to “revive” a car battery.

Assembling such a scheme is not difficult. If you do not plan to use the laptop charger for its intended purpose, you can cut off the plug and then connect the clamps to the wires. First, use a multimeter to determine the polarity. The light bulb is connected to a circuit that goes to the positive terminal of the battery. The negative terminal from the battery is connected directly. Only after connecting the device to the battery can voltage be supplied to the power supply.

DIY charger from a microwave oven or similar devices

Using the transformer block, which is located inside the microwave, you can make a charger for the battery.

Step-by-step instructions for making a homemade charger from a transformer block from a microwave are presented below.

Connection diagram of a transformer block, diode bridge and capacitor to a car battery

The device can be assembled on any base. It is important that all structural elements are reliably protected. If necessary, the circuit can be supplemented with a switch, as well as a voltmeter.

Transformerless charger

If the search for a transformer has led to a dead end, then you can use the simplest circuit without step-down devices. Below is a diagram that allows you to implement a charger for a battery without using voltage transformers.

Electrical circuit of the charger without using a voltage transformer

The role of transformers is performed by capacitors, which are designed for a voltage of 250V. The circuit should include at least 4 capacitors, placing them in parallel. A resistor and an LED are connected in parallel to the capacitors. The role of the resistor is to dampen the residual voltage after disconnecting the device from the network.

The circuit also includes a diode bridge designed to operate with currents up to 6A. The bridge is included in the circuit after the capacitors, and the wires going to the battery for charging are connected to its terminals.

How to charge a battery from a homemade device

Separately, you should understand the question of how to properly charge the battery with a homemade charger. To do this, it is recommended to adhere to the following recommendations:

- Maintain polarity. It is better to once again check the polarity of a homemade device with a multimeter rather than “biting your elbows”, because the cause of battery failure was an error with the wires.

- Do not test the battery by shorting the contacts. This method only “kills” the device, and does not revive it, as indicated in many sources.

- The device should be connected to a 220 V network only after the output terminals are connected to the battery. The device is turned off in the same way.

- Compliance with safety precautions, since work is carried out not only with electricity, but also with battery acid.

- The battery charging process must be monitored. The slightest malfunction can cause serious consequences.

Based on the above recommendations, it should be concluded that homemade devices, although acceptable, are still not capable of replacing factory ones. Making your own charger is not safe, especially if you are not confident that you can do it correctly. The material presents the simplest schemes for implementing chargers for car batteries, which will always be useful in the household.

Every motorist has experienced a moment in life when, after turning the key in the ignition, absolutely nothing happened. The starter would not turn, and as a result, the car would not start. The diagnosis is simple and clear: the battery is completely discharged. But having even the simplest one with an output voltage of 12 V on hand, you can restore the battery within one hour and go about your business. How to make such a device with your own hands is described later in the article.

How to properly charge a battery

Before you make a battery charger with your own hands, you should learn the basic rules regarding how to properly charge it. If you do not follow them, the battery life will sharply decrease and you will have to buy a new one, since it is almost impossible to restore the battery.

To set the correct current, you need to know a simple formula: the charge current is equal to the battery discharge current over a period of time equal to 10 hours. This means that the battery capacity should be divided by 10. For example, for a battery with a capacity of 90 A/h, the charge current must be set to 9 Amperes. If you supply more, the electrolyte will heat up quickly and the lead honeycomb may be damaged. At a lower current, it will take a very long time to fully charge.

Now we need to deal with the tension. For batteries whose potential difference is 12 V, the charging voltage should not exceed 16.2 V. This means that for one bank the voltage should be within 2.7 V.

The most basic rule for proper battery charging: do not mix up the terminals when connecting the battery. Incorrectly connected terminals are called polarity reversal, which will lead to immediate boiling of the electrolyte and final failure of the battery.

Required tools and supplies

You can make a high-quality charger with your own hands only if you have prepared tools and consumables under your hands.

List of tools and consumables:

- Multimeter. It should be in every motorist's tool bag. It will be useful not only when assembling the charger, but also in the future during repairs. A standard multimeter includes functions such as measuring voltage, current, resistance and continuity of conductors.

- Soldering iron. A power of 40 or 60 W is sufficient. You cannot use a soldering iron that is too powerful, as high temperatures will lead to damage to dielectrics, for example, in capacitors.

- Rosin. Necessary for a rapid increase in temperature. If the parts are not heated sufficiently, the soldering quality will be too low.

- Tin. The main fastening material is used to improve the contact of two parts.

- Heat-shrink tubing. A newer version of the old electrical tape, it is easy to use and has better dielectric properties.

Of course, tools such as pliers, a flat-head and shaped screwdriver should always be at hand. Having collected all the above elements, you can begin assembling the battery charger.

Sequence of manufacturing charging based on a switching power supply

Do-it-yourself battery charging should not only be reliable and of high quality, but also have a low cost. Therefore, the scheme below is ideal for achieving such goals.

Ready charging based on a switching power supply

What you will need:

- Electronic type transformer from the Chinese manufacturer Tashibra.

- Dinistor KN102. The foreign dinistor is marked DB3.

- Power keys MJE13007 in the amount of two pieces.

- Four KD213 diodes.

- A resistor with a resistance of at least 10 Ohms and a power of 10 W. If you install a lower power resistor, it will constantly heat up and very soon fail.

- Any feedback transformer that can be found in old radios.

You can place the circuit on any old board or buy a plate of inexpensive dielectric material for this. After assembling the circuit, it will need to be hidden in a metal case, which can be made from simple tin. The circuit must be isolated from the housing.

An example of a charger mounted in the case of an old system unit

The sequence of making a charger with your own hands:

- Remake the power transformer. To do this, you need to unwind its secondary winding, since Tashibra pulse transformers provide only 12 V, which is very little for a car battery. In place of the old winding, 16 turns of a new double wire should be wound, the cross-section of which will not be less than 0.85 mm. The new winding is insulated, and the next one is wound on top of it. Only now you need to make only 3 turns, the wire cross-section is at least 0.7 mm.

- Install short circuit protection. To do this you will need the same 10 ohm resistor. It should be soldered into the gap in the windings of the power transformer and the feedback transformer.

Resistor as short circuit protection

- Using four KD213 diodes, solder the rectifier. The diode bridge is simple, can operate with high frequency current, and is manufactured according to a standard design.

Diode bridge based on KD213A

- Making a PWM controller. Necessary in a charger, as it controls all power switches in the circuit. You can make it yourself using a field-effect transistor (for example, IRFZ44) and reverse conduction transistors. Elements of type KT3102 are ideal for these purposes.

PWM=high quality controller

- Connect the main circuit with the power transformer and the PWM controller. After which the resulting assembly can be secured in a self-made housing.

This charger is quite simple, does not require large expenses for assembly, and is lightweight. But circuits made on the basis of pulse transformers cannot be classified as reliable. Even the simplest standard power transformer will produce more stable performance than pulsed devices.

When working with any charger, remember that polarity reversal must not be allowed. This charging is protected from this, but still, mixed-up terminals shorten the service life of the battery, and a variable resistor in the circuit allows you to control the charging current.

Simple DIY charger

To make this charger, you will need elements that can be found in a used old-type TV. Before installing them in a new circuit, the parts must be checked with a multimeter.

The main part of the circuit is the power transformer, which cannot be found everywhere. Its marking: TS-180-2. A transformer of this type has 2 windings, the voltage of which is 6.4 and 4.7 V. To obtain the required potential difference, these windings should be connected in series - the output of the first should be connected to the input of the second by soldering or an ordinary terminal block.

Transformer type TS-180-2

You will also need four D242A type diodes. Since these elements will be assembled in a bridge circuit, excess heat will need to be removed from them during operation. Therefore, it is also necessary to find or purchase 4 cooling radiators for radio components with an area of at least 25 mm2.

All that remains is the base, for which you can take a fiberglass plate and 2 fuses, 0.5 and 10A. Conductors can be used of any cross-section, only the input cable must be at least 2.5 mm2.

Charger assembly sequence:

- The first element in the circuit is to assemble a diode bridge. It is assembled according to the standard scheme. The terminal locations should be lowered down, and all diodes should be placed on cooling radiators.

- From the transformer, from terminals 10 and 10′, draw 2 wires to the input of the diode bridge. Now you need to slightly modify the primary windings of the transformers, and to do this, solder a jumper between pins 1 and 1′.

- Solder the input wires to pins 2 and 2′. The input wire can be made from any cable, for example, from any used household appliance. If only a wire is available, then you need to attach a plug to it.

- A fuse rated at 0.5A should be installed in the gap in the wire leading to the transformer. In the positive gap, which will go directly to the battery terminal, there is a 10A fuse.

- The negative wire coming from the diode bridge is soldered in series to an ordinary lamp rated at 12 V, with a power of no more than 60 W. This will help not only control battery charging, but also limit the charging current.

All elements of this charger can be placed in a tin case, also made by hand. Fix the fiberglass plate with bolts, and mount the transformer directly on the housing, having previously placed the same fiberglass plate between it and the sheet metal.

Ignoring the laws of electrical engineering can lead to the charger constantly failing. Therefore, it is worth planning the charging power in advance, depending on which to assemble the circuit. If you exceed the power of the circuit, then the battery will not be properly charged unless the operating voltage is exceeded.

Sooner or later, the car may stop starting due to low battery charge. Long-term operation leads to the fact that the generator is no longer able to charge the battery. In this case, it is necessary keep at least a simple charger on hand for a car battery.

Nowadays, conventional transformer charging is being replaced by a new generation of improved models. Pulse and automatic chargers are very popular among them. Let's get acquainted with the principle of their work, and for those who already want to tinker, go

Pulse chargers for batteries

Unlike a transformer, a pulse charger for a car battery provides a full charge. However, its main advantages are ease of use, significantly lower price and compact size.

Unlike a transformer, a pulse charger for a car battery provides a full charge. However, its main advantages are ease of use, significantly lower price and compact size.

Charging the battery with pulsed devices is carried out in two stages: first at constant voltage, and then at constant current(often the charging process is automated). Basically, modern chargers consist of the same type, but very complex circuits, so if they break down, it is better for an inexperienced owner to purchase a new one.

Lead acid batteries are very sensitive to temperature. In hot weather, the battery charge level should not be lower than 50%, and in severe frost conditions, not lower than 75%. Otherwise, the battery may stop working and will need to be recharged. Pulse devices are very suitable for this and do not damage the battery.

Automatic chargers for car batteries

For inexperienced drivers, an automatic charger is best for a car battery. It has a number of functions and protections that will notify you of incorrect pole connection and prohibit the flow of electric current.

For inexperienced drivers, an automatic charger is best for a car battery. It has a number of functions and protections that will notify you of incorrect pole connection and prohibit the flow of electric current.

Some devices are designed to measure the capacity and charge level of a battery, so they are used to charge any type of battery.

The electrical circuits of automatic devices contain a special timer, thanks to which several different cycles can be carried out: full charging, fast charging and battery recovery. After the process is completed the device will inform you about this and turn off the load.

Very often, due to improper use of the battery, sulfitation forms on its plates. The charge-discharge cycle not only rids the battery of salts that have appeared, but also extends its service life.

Despite the low price of modern chargers, there are times when proper charging is not at hand. That's why It’s quite possible to make a charger for a car battery with your own hands. Let's look at a few examples of homemade devices.

Charging the battery from the computer power supply

Some people may still have old computers with a working power supply that could make an excellent charger. It is suitable for almost any battery. Circuit diagram of a simple charger from a computer power supply

Circuit diagram of a simple charger from a computer power supply

Almost every power supply has a PWM controller in place of DA1 - a controller based on a TL494 chip or a similar KA7500. To charge the battery, a current of 10% of the full battery capacity is required(usually from 55 to 65A*h), so any power supply with a power of over 150 W is capable of producing it. Initially, you need to unsolder unnecessary wires from sources -5 V, -12 V, +5 V, +12 V.

Next, you need to unsolder resistor R1, which is replaced with a trimming resistor with the highest value of 27 kOhm. The voltage from the +12 V bus will be transmitted to the upper pin. Then pin 16 is disconnected from the main wire, and pins 14 and 15 are simply cut at the connection point.

This is approximately what a power supply unit should look like at the initial stage of rework.

Now a potentiometer-current regulator R10 is installed on the back wall of the power supply, and 2 cords are passed through: one for network, the other for connecting to the battery terminals. It is recommended to prepare a block of resistors in advance, with the help of which connection and adjustment are much more convenient.

To manufacture it, two current measuring resistors 5W8R2J with a power of 5 W are connected in parallel. Eventually the total power reaches 10 W, and the required resistance is 0.1 Ohm. To set up the charger, a trimming resistor is attached to the same board. Some part of the print track needs to be removed. This will help eliminate the possibility of unwanted connections between the device body and the main circuit. You should pay attention to this for 2 reasons:

Electrical connections and a board with a resistor block are installed according to the above diagram.

Pins 1, 14, 15, 16 on the chip first you should tin the wires and then solder them.

Full charge will be determined by open circuit voltage ranging from 13.8 to 14.2 V. It must be set with a variable resistor with the potentiometer R10 in the middle position. To connect the leads to the battery terminals, alligator clips are installed at their ends. The insulating tubes on the clamps must be of different colors. Typically, red corresponds to “plus” and black to “minus”. Do not get confused with connecting wires, otherwise this will lead to damage to the device..

Ultimately, a charger for a car battery from a computer power supply should look something like this.

If the charger will be used exclusively for charging the battery, then you can dispense with the volt and ammeter. To set the initial current, it is enough to use the graduated scale of potentiometer R10 with a value of 5.5-6.5 A. Almost the entire charging process does not require human intervention.

This type of charger eliminates the possibility of overheating or overcharging the battery.

The simplest memory using an adapter

An adapted 12-volt adapter acts as a DC source here.. In this case, a charger circuit for a car battery is not required.

An adapted 12-volt adapter acts as a DC source here.. In this case, a charger circuit for a car battery is not required.

The main thing to take into account is an important feature - The voltage of the power source must be equal to the voltage of the battery itself, otherwise the battery will not charge.

The end of the adapter wire is cut off and exposed to 5 cm. Next, the wires with opposite charges are separated from each other by 40 cm. Then a crocodile is placed on the end of each wire(type of terminals), each of which should be a different color to avoid confusion with polarity. The clamps are connected in series to the battery (“from plus to plus”, “from minus to minus”) and then the adapter is turned on.

The only difficulty is choosing the right power source. It is also worth paying attention to the fact that the battery may overheat during the process. In this case, you need to interrupt charging for a while.

A xenon lamp is one of the best light sources for cars. Find out what the penalty is for xenon before installing it.

Anyone can install parking sensors. You can verify this on this page. Go ahead and find out how to install parking sensors yourself.

Many drivers have proven that the Strelka police radar does not forgive mistakes. By following this link /tuning/elektronika/radar-detektor-protiv-strelki.html you can find out which radar detectors can protect the driver from a fine.

Charger made from a household light bulb and diode

To create a simple memory you will need a few simple elements:

- household light bulb with a power of up to 200 W. The speed of battery charging depends on its power - the higher the faster;

- A semiconductor diode that conducts electricity in only one direction. As such a diode You can use a laptop charger;

- wires with terminals and plug.

The connection diagram of the elements and the battery charging process are clearly demonstrated in this video.

If the circuit is configured correctly, the light bulb will burn at full intensity, and if it does not light up at all, then the circuit needs to be modified. It is possible that the light will not light up if the battery is fully charged, which is unlikely (the voltage at the terminals is high and the current value is low).

Charging takes approximately 10 hours, after which be sure to unplug the charger, otherwise overheating of the battery will lead to its failure.

In emergency cases, you can recharge the battery using a sufficiently powerful diode and a heater using current from the mains. The sequence of connecting to the network should be as follows: diode, heater, battery. This method consumes a large amount of electricity, and the efficiency is significantly low - 1%. This homemade charger for a car battery can be considered the simplest, but extremely unreliable.

Conclusion

Creating the simplest charger that will not damage your battery will require a lot of technical knowledge. WITH There is now a wide selection of chargers on the market with great functionality and a simple interface to work with.

Creating the simplest charger that will not damage your battery will require a lot of technical knowledge. WITH There is now a wide selection of chargers on the market with great functionality and a simple interface to work with.

Therefore, if possible, it is better to have a reliable device with you with a guarantee that the battery will not be compromised and will continue to operate reliably.

Take a look at this video. It shows another way to quickly charge the battery with your own hands.

Every car owner needs a battery charger, but it costs a lot, and regular preventive trips to a car service center are not an option. Battery service at a service station takes time and money. In addition, with a discharged battery, you still need to drive to the service station. Anyone who knows how to use a soldering iron can assemble a working charger for a car battery with their own hands.

A little theory about batteries

Any battery is a storage device for electrical energy. When voltage is applied to it, energy is stored due to chemical changes inside the battery. When a consumer is connected, the opposite process occurs: a reverse chemical change creates voltage at the terminals of the device, and current flows through the load. Thus, in order to get voltage from the battery, you first need to “put it down,” that is, charge the battery.

Almost any car has its own generator, which, when the engine is running, provides power to the on-board equipment and charges the battery, replenishing the energy spent on starting the engine. But in some cases (frequent or difficult engine starts, short trips, etc.) the battery energy does not have time to be restored, and the battery is gradually discharged. There is only one way out of this situation - charging with an external charger.

How to find out the battery status

To decide whether charging is necessary, you need to determine the state of the battery. The simplest option - “turns/does not turn” - is at the same time unsuccessful. If the battery “doesn’t turn”, for example, in the garage in the morning, then you won’t go anywhere at all. The “does not turn” condition is critical, and the consequences for the battery can be dire.

To decide whether charging is necessary, you need to determine the state of the battery. The simplest option - “turns/does not turn” - is at the same time unsuccessful. If the battery “doesn’t turn”, for example, in the garage in the morning, then you won’t go anywhere at all. The “does not turn” condition is critical, and the consequences for the battery can be dire.

The optimal and reliable method for checking the condition of a battery is to measure the voltage on it with a conventional tester. At an air temperature of about 20 degrees dependence of the degree of charge on voltage on the terminals of the battery disconnected from the load (!) is as follows:

- 12.6…12.7 V - fully charged;

- 12.3…12.4 V - 75%;

- 12.0…12.1 V - 50%;

- 11.8…11.9 V - 25%;

- 11.6…11.7 V - discharged;

- below 11.6 V - deep discharge.

It should be noted that the voltage of 10.6 volts is critical. If it drops below, the “car battery” (especially a maintenance-free one) will fail.

Correct charging

There are two methods of charging a car battery - constant voltage and constant current. Everyone has their own features and disadvantages:

Homemade battery chargers

Assembling a charger for a car battery with your own hands is realistic and not particularly difficult. To do this, you need to have basic knowledge of electrical engineering and be able to hold a soldering iron in your hands.

Simple 6 and 12 V device

This scheme is the most basic and budget-friendly. Using this charger, you can efficiently charge any lead-acid battery with an operating voltage of 12 or 6 V and an electrical capacity of 10 to 120 A/h.

The device consists of a step-down transformer T1 and a powerful rectifier assembled using diodes VD2-VD5. The charging current is set by switches S2-S5, with the help of which quenching capacitors C1-C4 are connected to the power circuit of the primary winding of the transformer. Thanks to the multiple “weight” of each switch, various combinations allow you to stepwise adjust the charging current in the range of 1–15 A in 1 A increments. This is enough to select the optimal charging current.

For example, if a current of 5 A is required, then you will need to turn on the toggle switches S4 and S2. Closed S5, S3 and S2 will give a total of 11 A. To monitor the voltage on the battery, use a voltmeter PU1, the charging current is monitored using an ammeter PA1.

The design can use any power transformer with a power of about 300 W, including homemade ones. It should produce a voltage of 22–24 V on the secondary winding at a current of up to 10–15 A. In place of VD2-VD5, any rectifier diodes that can withstand a forward current of at least 10 A and a reverse voltage of at least 40 V are suitable. D214 or D242 are suitable. They should be installed through insulating gaskets on a radiator with a dissipation area of at least 300 cm2.

Capacitors C2-C5 must be non-polar paper with an operating voltage of at least 300 V. Suitable, for example, are MBChG, KBG-MN, MBGO, MBGP, MBM, MBGCh. Similar cube-shaped capacitors were widely used as phase-shifting ones for electric motors in household appliances. A DC voltmeter of type M5−2 with a measurement limit of 30 V was used as PU1. PA1 is an ammeter of the same type with a measurement limit of 30 A.

The circuit is simple, if you assemble it from serviceable parts, then it does not need adjustment. This device is also suitable for charging six-volt batteries, but the “weight” of each of the switches S2-S5 will be different. Therefore, you will have to navigate the charging currents using an ammeter.

With continuously adjustable current

Using this scheme, it is more difficult to assemble a charger for a car battery with your own hands, but it can be repeated and also does not contain scarce parts. With its help, it is possible to charge 12-volt batteries with a capacity of up to 120 A/h, the charge current is smoothly regulated.

The battery is charged using a pulsed current; a thyristor is used as a regulating element. In addition to the knob for smoothly adjusting the current, this design also has a mode switch, when turned on, the charging current doubles.

The charging mode is controlled visually using the RA1 dial gauge. Resistor R1 is homemade, made of nichrome or copper wire with a diameter of at least 0.8 mm. It serves as a current limiter. Lamp EL1 is an indicator lamp. In its place, any small-sized indicator lamp with a voltage of 24–36 V will do.

A step-down transformer can be used ready-made with an output voltage on the secondary winding of 18–24 V at a current of up to 15 A. If you don’t have a suitable device at hand, you can make it yourself from any network transformer with a power of 250–300 W. To do this, wind all windings from the transformer except the mains winding, and wind one secondary winding with any insulated wire with a cross-section of 6 mm. sq. The number of turns in the winding is 42.

Thyristor VD2 can be any of the KU202 series with the letters V-N. It is installed on a radiator with a dispersion area of at least 200 sq. cm. The power installation of the device is done with wires of minimal length and with a cross-section of at least 4 mm. sq. In place of VD1, any rectifier diode with a reverse voltage of at least 20 V and withstanding a current of at least 200 mA will work.

Setting up the device comes down to calibrating the RA1 ammeter. This can be done by connecting several 12-volt lamps with a total power of up to 250 W instead of a battery, monitoring the current using a known-good reference ammeter.

From a computer power supply

To assemble this simple charger with your own hands, you will need a regular power supply from an old ATX computer and knowledge of radio engineering. But the characteristics of the device will be decent. With its help, batteries are charged with a current of up to 10 A, adjusting the current and charge voltage. The only condition is that the power supply is desirable on the TL494 controller.

For creating DIY car charging from a computer power supply you will have to assemble the circuit shown in the figure.

Step by step steps required to finalize the operation will look like this:

- Bite off all the power bus wires, with the exception of the yellow and black ones.

- Connect the yellow and separately black wires together - these will be the “+” and “-” chargers, respectively (see diagram).

- Cut all traces leading to pins 1, 14, 15 and 16 of the TL494 controller.

- Install variable resistors with a nominal value of 10 and 4.4 kOhm on the power supply casing - these are the controls for regulating the voltage and charging current, respectively.

- Using a suspended installation, assemble the circuit shown in the figure above.

If the installation is done correctly, then the modification is complete. All that remains is to equip the new charger with a voltmeter, an ammeter and wires with alligator clips for connecting to the battery.

In the design it is possible to use any variable and fixed resistors, except for the current resistor (the lower one in the circuit with a nominal value of 0.1 Ohm). Its power dissipation is at least 10 W. You can make such a resistor yourself from a nichrome or copper wire of the appropriate length, but you can actually find a ready-made one, for example, a 10 A shunt from a Chinese digital tester or a C5-16MV resistor. Another option is two 5WR2J resistors connected in parallel. Such resistors are found in switching power supplies for PCs or TVs.

What you need to know when charging a battery

When charging a car battery, it is important to follow a number of rules. This will help you Extend battery life and maintain your health:

The question of creating a simple battery charger with your own hands has been clarified. Everything is quite simple, all you have to do is stock up on the necessary tools and you can safely get to work.

Very often, especially in the cold season, car enthusiasts are faced with the need to charge a car battery. It is possible, and advisable, to purchase a factory charger, preferably a charging and starting one for use in the garage.

But, if you have electrical engineering skills and certain knowledge in the field of radio engineering, then you can make a simple charger for a car battery with your own hands. In addition, it is better to prepare in advance for the possible event that the battery suddenly discharges far from home or a place where it is parked and serviced.

General information about the battery charging process

Charging a car battery is necessary when the voltage drop across the terminals is less than 11.2 Volts. Despite the fact that the battery can start the car engine even with such a charge, during long-term parking at low voltages, plate sulfation processes begin, which lead to loss of battery capacity.

Therefore, when wintering a car in a parking lot or garage, it is necessary to constantly recharge the battery and monitor the voltage at its terminals. A better option is to remove the battery, put it in a warm place, but still remember to maintain its charge.

The battery is charged using constant or pulsed current. In the case of charging from a constant voltage source, a charge current equal to one tenth of the battery capacity is usually selected.

For example, if the battery capacity is 60 Amp-hours, the charging current should be selected at 6 Amp. However, research shows that the lower the charge current, the less intense the sulfation processes.

Moreover, there are methods for desulfating battery plates. They are as follows. First, the battery is discharged to a voltage of 3 - 5 Volts with high currents of short duration. For example, such as when turning on the starter. Then there is a slow full charge with a current of about 1 Ampere. Such procedures are repeated 7-10 times. There is a desulfation effect from these actions.

Desulfating pulse chargers are practically based on this principle. The battery in such devices is charged with pulsed current. During the charging period (several milliseconds), a short discharge pulse of reverse polarity and a longer charging pulse of direct polarity are applied to the battery terminals.

It is very important during the charging process to prevent the effect of overcharging the battery, that is, the moment when it is charged to the maximum voltage (12.8 - 13.2 Volts, depending on the type of battery).

This can cause an increase in the density and concentration of the electrolyte, irreversible destruction of the plates. That is why factory chargers are equipped with an electronic control and shutdown system.

Schemes of homemade simple chargers for a car battery

Protozoa

Let's consider the case of how to charge a battery using improvised means. For example, a situation when you left your car near your house in the evening, forgetting to turn off some electrical equipment. By morning the battery was discharged and would not start the car.

In this case, if your car starts well (with half a turn), it is enough to “tighten” the battery a little. How to do it? First, you need a constant voltage source ranging from 12 to 25 volts. Secondly, restrictive resistance.

What can you recommend?

Nowadays, almost every home has a laptop. The power supply of a laptop or netbook, as a rule, has an output voltage of 19 Volts and a current of at least 2 amperes. The external pin of the power connector is minus, the internal pin is positive.

As a limiting resistance, and it is mandatory!!!, you can use the car's interior light bulb. You can, of course, have more power from turn signals or even worse stops or dimensions, but there is a possibility of overloading the power supply. The simplest circuit is assembled: minus the power supply - light bulb - minus the battery - plus the battery - plus the power supply. In a couple of hours the battery will be charged enough to start the engine.

If you don’t have a laptop, you can pre-purchase a powerful rectifier diode on the radio market with a reverse voltage of more than 1000 Volts and a current of 3 Amperes. It is small in size and can be put in the glove compartment for an emergency.

What to do in an emergency?

Conventional lamps can be used as a limiting load incandescent at 220 Volt. For example, a 100 Watt lamp (power = voltage X current). Thus, when using a 100-watt lamp, the charge current will be about 0.5 Ampere. Not much, but overnight it will give 5 Amp-hours of capacity to the battery. Usually it is enough to crank the car starter a couple of times in the morning.

If you connect three 100-watt lamps in parallel, the charging current will triple. You can charge your car battery almost halfway overnight. Sometimes they turn on an electric stove instead of lamps. But here the diode may already fail, and at the same time the battery.

In general, this kind of experiments with direct charging of the battery from an alternating voltage network of 220 Volts extremely dangerous. They should only be used in extreme cases when there is no other option.

From computer power supplies

Before you start making your own charger for a car battery, you should evaluate your knowledge and experience in the field of electrical and radio engineering. In accordance with this, select the complexity level of the device.

First of all, you should decide on the element base. Very often, computer users are left with old system units. There are power supplies there. Along with the +5V supply voltage, they contain a +12 Volt bus. As a rule, it is designed for current up to 2 Amperes. This is quite enough for a weak charger.

Video - step-by-step manufacturing instructions and diagram of a simple charger for a car battery from a computer power supply:

But 12 volts is not enough. It is necessary to “overclock” it to 15. How? Usually using the “poke” method. Take a resistance of about 1 kiloOhm and connect it in parallel with other resistances near the microcircuit with 8 legs in the secondary circuit of the power supply.

Thus, the transmission coefficient of the feedback circuit changes, respectively, and the output voltage.

It’s difficult to explain in words, but usually users succeed. By selecting the resistance value, you can achieve an output voltage of about 13.5 Volts. This is enough to charge a car battery.

If you don’t have a power supply at hand, you can look for a transformer with a secondary winding of 12 - 18 Volts. They were used in old tube televisions and other household appliances.

Now such transformers can be found in used uninterruptible power supplies; they can be bought for pennies on the secondary market. Next, we begin manufacturing the transformer charger.

Transformer chargers

Transformer chargers are the most common and safe devices widely used in automotive practice.

Video - a simple charger for a car battery using a transformer:

The simplest circuit of a transformer charger for a car battery contains:

- network transformer;

- rectifier bridge;

- restrictive load.

A large current flows through the limiting load and it gets very hot, so to limit the charging current, capacitors are often used in the primary circuit of the transformer.

In principle, in such a circuit you can do without a transformer if you choose the capacitor wisely. But without galvanic isolation from the AC network, such a circuit will be dangerous from the point of view of electric shock.

More practical are charger circuits for car batteries with regulation and limitation of the charge current. One of these schemes is shown in the figure:

You can use the rectifier bridge of a faulty car generator as powerful rectifier diodes by slightly reconnecting the circuit.

More complex pulse chargers with desulfation function are usually made using microcircuits, even microprocessors. They are difficult to manufacture and require special installation and configuration skills. In this case, it is easier to purchase a factory device.

Safety requirements

Conditions that must be met when using a homemade car battery charger:

- The charger and battery must be located on a fireproof surface during charging;

- when using simple chargers, it is necessary to use personal protective equipment (insulating gloves, rubber mat);

- when using newly manufactured devices, constant monitoring of the charging process is necessary;

- the main controlled parameters of the charging process are current, voltage at the battery terminals, temperature of the charger body and battery, control of the boiling point;

- When charging at night, it is necessary to have residual current devices (RCDs) in the network connection.

Video - diagram of a charger for a car battery from a UPS:

May be of interest:

Scanner for self-diagnosis of a car

How to quickly get rid of scratches on a car body

What are the benefits of installing autobuffers?

Mirror DVR Car DVRs Mirror

Similar articles

Comments on the article:

Lyokha

The information presented here is certainly interesting and informative. As a former radio engineer of the Soviet school, I read it with great interest. But in reality, now even “desperate” radio amateurs are unlikely to bother searching for circuit diagrams for a homemade charger and later assembling it with a soldering iron and radio components. Only radio fanatics will do this. It’s much easier to buy a factory-made device, especially since the prices, I think, are affordable. As a last resort, you can turn to other car enthusiasts with a request to “light up”, fortunately, now there are plenty of cars everywhere. What is written here is useful not so much for its practical value (although that too), but for instilling interest in radio engineering in general. After all, most modern children not only cannot distinguish a resistor from a transistor, but they won’t be able to pronounce it the first time. And this is very sad...

Michael

When the battery was old and half-dead, I often used a laptop power supply to recharge. As a current limiter I used an unnecessary old taillight with four 21-watt bulbs connected in parallel. I control the voltage at the terminals, at the beginning of charging it is usually about 13 V, the battery greedily eats up the charge, then the charging voltage increases, and when it reaches 15 V, I stop charging. It takes half an hour to an hour to reliably start the engine.

Ignat

I have a Soviet charger in my garage, it’s called “Volna”, made in ’79. Inside is a hefty and heavy transformer and several diodes, resistors and transistors. Almost 40 years in service, and this despite the fact that my father and brother use it constantly, not only for charging, but also as a 12 V power supply. And now, indeed, it’s easier to buy a cheap Chinese device for five hundred square meters than to bother with soldering iron. And on Aliexpress you can even buy it for one and a half hundred, although it will take a long time to send it. Although I liked the option from the computer power supply, I have a dozen old ones lying around in the garage, but they work quite well.

San Sanych

Hmmm. Of course, the Pepsicol generation is growing... :-\ The correct charger should produce 14.2 volts. No more and no less. With a greater potential difference, the electrolyte will boil, and the battery will swell so that it will then be problematic to remove it or, conversely, not to install it back in the car. With a smaller potential difference, the battery will not charge. The most normal circuit presented in the material is with a step-down transformer (first). In this case, the transformer must produce exactly 10 volts at a current of at least 2 amperes. There are plenty of these on sale. It is better to install domestic diodes - D246A (must be installed on a radiator with mica insulators). At worst - KD213A (these can be glued to an aluminum radiator with superglue). Any electrolytic capacitor with a capacity of at least 1000 uF for an operating voltage of at least 25 volts. A very large capacitor is also not needed, since due to the ripples of the under-rectified voltage we obtain the optimal charge for the battery. In total we get 10 * root of 2 = 14.2 volts. I myself have had such a charger since the days of the 412th Muscovite. Not killable at all. 🙂

Kirill

In principle, if you have the necessary transformer, it is not so difficult to assemble a transformer charger circuit yourself. Even for me, not a very big specialist in the field of radio electronics. Many people say, why bother if it’s easier to buy. I agree, but this is not about the final result, but about the process itself, because it is much more pleasant to use something made with your own hands than something purchased. And most importantly, if this homemade product breaks down, then the one who assembled it knows his battery charger thoroughly and is able to fix it quickly. And if a purchased product burns out, then you still need to dig around and it’s not at all a fact that a breakdown will be found. I vote for self-built devices!

Oleg

In general, I think that the ideal option is an industrial charger, so I have one and carry it in the trunk all the time. But in life situations are different. Once I was visiting my daughter in Montenegro, and there they generally don’t carry anything with them and rarely do anyone even have one. So she forgot to close the door at night. The battery is drained. No diode at hand, no computer. I found a Boschevsky screwdriver with 18 volts and 1 ampere current. So I used his charger. True, I charged it all night and periodically checked for overheating. But she couldn’t stand it, in the morning they started her with half a kick. So there are many options, you have to look. Well, regarding homemade chargers, as a radio engineer I can only recommend transformer ones, i.e. isolated via the network, they are safe compared to capacitors, diodes with a light bulb.

Sergey

Charging the battery with non-standard devices can lead to either complete irreversible wear or a decrease in guaranteed operation. The whole problem is connecting homemade products, so that the rated voltage does not exceed the permissible one. It is necessary to take into account temperature changes and this is a very important point, especially in winter. When we decrease by a degree, we increase it and vice versa. There is an approximate table depending on the type of battery - it is not difficult to remember. Another important point is that all measurements of voltage and, of course, density are made only when the engine is cold, with the engine not running.

Vitalik

In general, I use the charger extremely rarely, maybe once every two or three years, and only when I go away for a long time, for example in the summer for a couple of months to the south to visit relatives. And so basically the car is in operation almost every day, the battery is charged and there is no need for such devices. Therefore, I think that buying for money something that you practically never use is not very smart. The best option is to assemble such a simple craft, say from a computer power supply, and let it lie around, waiting in the wings. After all, the main thing here is not to fully charge the battery, but to cheer it up a little to start the engine, and then the generator will do its job.

Nikolay

Just yesterday we recharged the battery using a screwdriver charger. The car was parked outside, the frost was -28, the battery was spun a couple of times and stopped. We took out a screwdriver, a couple of wires, connected it, and after half an hour the car started up safely.

Dmitriy

A ready-made store charger is of course an ideal option, but who wants to use their own hands, and considering that you don’t have to use it often, you don’t have to spend money on the purchase and do the charging yourself.

A homemade charger should be autonomous, not require supervision or current control, since we charge most often at night. In addition, it must provide a voltage of 14.4 V and ensure that the battery is turned off when the current and voltage exceed the norm. It should also provide protection against polarity reversal.

The main mistakes that “Kulibins” make are connecting directly to a household electrical network, this is not even a mistake, but a violation of safety regulations, the next limiting the charging current is by capacitors, and it’s also more expensive: one bank of capacitors 32 uF at 350-400 V (less than that is not possible) will cost like a cool branded charger.

The easiest way is to use a computer switching power supply (UPS), it is now more affordable than a hardware transformer, and you don’t need to do separate protection, everything is ready.

If you don't have a computer power supply, you need to look for a transformer. A power supply with filament windings from old tube TVs - TS-130, TS-180, TS-220, TS-270 - is suitable. They have plenty of power behind their eyes. You can find an old TN filament transformer at the car market.

But all this is only for those who are friends with electricians. If not, don’t bother - you won’t do the exercises that meet all the requirements, so buy ready-made ones and don’t waste time.

Laura

I got a charger from my grandfather. Since Soviet times. Homemade. I don’t understand this at all, but when my friends see it, they click their tongues in admiration and respect, saying, this is a thing “for centuries.” They say it was assembled using some lamps and still works. True, I practically don’t use it, but that’s not the point. Everyone criticizes Soviet technology, but it turns out to be many times more reliable than modern technology, even homemade ones.

Vladislav

In general, a useful thing in the household, especially if there is a function for adjusting the output voltage

Alexei

I’ve never had the opportunity to use or assemble homemade chargers, but I can quite imagine the principle of assembly and operation. I think that homemade products are no worse than factory ones, it’s just that no one wants to tinker, especially since store-bought ones are quite affordable.

Victor

In general, the schemes are simple, there are few parts and they are accessible. Adjustment can also be done if you have some experience. So it's quite possible to collect. Of course, it is very pleasant to use a device assembled with your own hands)).

Ivan

The charger is, of course, a useful thing, but now there are more interesting specimens on the market - their name is start-chargers

Sergey

There are a lot of charger circuits and as a radio engineer I have tried many of them. Until last year, I had a scheme that worked for me since Soviet times and it worked perfectly. But one day (through my fault) the battery completely died in the garage and I needed a cyclic mode to restore it. Then I didn’t bother (due to lack of time) with creating a new circuit, but just went and bought it. And now I carry a charger in the trunk just in case.